Impact of Phytase-Supplemented Palm Kernel Cake on Growth, Feed Efficiency, and Economic Viability in Poultry

Abstract

The rising costs of conventional poultry feed ingredients, such as soybean, maize, and fish meal, have prompted the search for more affordable and sustainable alternatives in poultry production. This study investigates the use of phytase-supplemented Palm Kernel Cake (PKC) as a replacement for soybean meal to improve feed efficiency, nutrient absorption, and growth performance in poultry. White Leghorn layers, Rhode Island Red layers, broilers, and cockerels were fed three different feed formulations: conventional feed (CF), Moderate PKC with Phytase (MPP), and High PKC with Phytase (HPP). The results showed that PKC-based diets significantly reduced feed costs while maintaining satisfactory growth, although CF led to higher body weight gain and feed efficiency. The MPP formulation struck an optimal balance between cost savings and nutritional quality, making it a viable option for layers and cockerels, while CF remained the most effective for broilers. While the HPP formulation resulted in lower feed costs, it compromised weight gain and overall profitability. These findings highlight the potential of phytase-enhanced PKC as a sustainable, cost-effective alternative to conventional feed, particularly in regions with high feed costs. However, the study emphasizes the importance of balancing cost reductions with feed quality to maximize profitability. Future research should focus on optimizing PKC inclusion levels and exploring additional enzyme supplements to further enhance feed efficiency and support sustainable poultry farming practices. This study provides valuable insights into how strategic feed formulation can support both economic and production goals in the poultry industry.

Author Contributions

Academic Editor: Anubha Bajaj, Consultant Histopathologist, A.B. Diagnostics, Delhi, India

Checked for plagiarism: Yes

Review by: Single-blind

Copyright © 2025 Kwamina Ewur Banson, et al

This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Competing interests

The authors have declared that no competing interests exist.

Citation:

Introduction

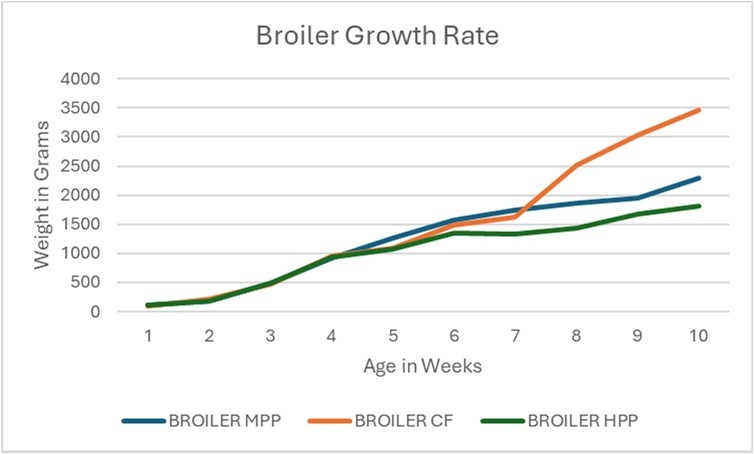

Poultry feed accounts for a significant portion of production costs, both for meat and egg production 1. Global disruptions, such as the COVID-19 pandemic, African Swine Fever, and geopolitical tensions, have caused major spikes in feed prices, particularly in essential components like maize and soybean meal 2, 3, 4, 5. This has been especially true in Ghana, where poultry producers are heavily reliant on these imported feedstuffs 6, 7. Figure 1 demonstrates the escalation in prices for these key ingredients, putting a strain on local farmers and necessitating the exploration of alternative feeds.

Figure 1.Feed Ingredients prices of livestock diet, SECC, BNARI Research

Palm Kernel Cake (PKC) is an abundant by-product in Ghana and offers a cost-effective protein source, though it has limitations in amino acid profile and digestibility compared to soybean meal 8, 9, 10. This study investigates the potential for PKC, combined with phytase supplementation, to replace soybean meal in poultry diets, aiming to reduce feed costs without sacrificing growth and productivity. Phytase, an enzyme that improves phosphorus and amino acid availability, may counterbalance the lower digestibility of PKC, making it a viable solution for local poultry nutrition challenges 11, 12.

With the rising costs of feed components, these factors become even more critical, as increased feed prices directly affect the economic viability of poultry production. Optimizing feed formulations and closely managing intake will be essential for maintaining profitability considering escalating feed costs.

PKC is a by-product of palm oil extraction and is widely available in Ghana. While PKC offers a lower-cost protein alternative nutrition with approximately 16-20% of crude protein (CP), its amino acid profile and digestibility are inferior to soybean meal 13, 14, 15. This study investigates the impact of replacing soybean meal with PKC in broiler, layer, and cockerel diets, with and without Phytase, on growth performance, feed efficiency, and economic returns.

Analysts from the Socioeconomics and Commercialisation Center (SECC) of the Biotechnology and Nuclear Agriculture Research Institute (BNARI) predict that feed prices will continue to rise 16. Figure 1 illustrates the increase in prices for key raw materials used in pig and chicken feed over previous years. These are actual price trends, and it is evident that no significant price reductions are expected, as climate change continues to impact farming practices, leading to disrupted cultivation trends and failing crops 17. As a result, relying on alternative feed materials and increasing the inclusion of by-products will be essential to reducing feed costs and maintaining economic viability in poultry and pig production. In Ghana, several alternative protein sources are commonly used to replace expensive soybean and fish meal in animal feed. Here are some examples:

Palm Kernel Cake (PKC)

A byproduct of palm oil extraction, palm kernel cake is a good source of protein and fiber. It is widely used in livestock feed due to its relatively low cost compared to soybean and fish meal.

Cotton Seed Meal

This is a byproduct of cottonseed oil extraction. It is high in protein and is often used in poultry and pig feeds. However, it should be used with caution due to the presence of gossypol, which can be toxic in high amounts.

Groundnut Meal (Peanut Meal)

Produced from groundnuts (peanuts), this meal is rich in protein and is a common ingredient in animal feed. It's a cost-effective alternative to soybean meal.

Brewer's Spent Grain (BSG)

This is a byproduct of the brewing industry. While not as high in protein as other sources, it is a good source of fiber and can be used as a partial substitute for other feed ingredients.

Alternative energy sources can include bakery by-products. Corn chaff and by products of wheat. Formulating animal diet is depended on the ability of the amino acid levels to be absorbed.

PKC, despite its economic advantages, has inferior amino acid profiles and higher levels of anti-nutritional factors like gossypol and trypsin inhibitors, which limit its digestibility and nutrient availability 18. The inclusion of phytase in PKC-based feeds is intended to mitigate these issues by enhancing phosphorus and amino acid absorption. Phytase’s role in breaking down phytic acid, a component in many plant-based feeds that reduces nutrient bioavailability, makes it an essential additive to improve the overall feed efficiency of alternative protein sources like PKC 19.

Moderate PKC Inclusion (20%)

Studies have shown that moderate PKC levels, such as 20%, can be used without significantly compromising growth performance when enzyme supplementation is included. For instance, research by Alshelmani, Bakhashwain 20 found that incorporating 20% PKC with phytase in broiler diets provided sufficient energy and protein while maintaining growth performance. The addition of phytase helped improve phosphorus availability, compensating for the lower digestibility of PKC due to its high fiber content. Other studies, like Sundu and Inoue 21, have also observed that 20% PKC can be a viable substitute for traditional feed ingredients when supported by enzyme supplementation to mitigate anti-nutritional factors.

High PKC Inclusion (50%)

Higher PKC levels (around 50%) are often tested to determine the upper threshold for effective use in poultry diets. However, as Abioja, Ayo 22 noted, high PKC levels in poultry feed tend to reduce growth performance due to fibre’s impact on nutrient digestibility. Adding enzymes like phytase, however, has shown promise in countering some of these negative effects by breaking down phytates and enhancing phosphorus release, thus supporting nutrient absorption. Okeudo and Odaibo 23 reported that while broilers could tolerate higher PKC levels with enzyme supplementation, growth efficiency decreased at these higher levels compared to moderate inclusion rates. This aligns with the purpose of including a 50% PKC level in experiments—to test the upper limits of PKC use while using phytase to optimize its nutrient value.

Materials and Methods

This study was carried out at BNARI's intensive poultry farm in Kwabenya, Ghana, during a period of significant feed price inflation between 2023 and 2024. A total of 132 day-old chicks were sourced from a commercial supplier, consisting of 33 Cobb-500 broilers, 33 White Leghorn layers, 33 Rhode Island Red layers, and 33 cockerels. Each group of 33 birds was further divided into three replications of 11 birds per group. While large-scale nutrition trials often utilize 6–12 replicates per treatment to maximize statistical robustness, our study was conducted within the logistical and ethical constraints of our facility, which limited the number of replicates. Under such conditions, small-pen studies commonly employ three replicates per treatment, a practice that is scientifically acceptable for preliminary or resource-limited research 24, 25. All birds were managed under uniform housing and environmental conditions to reduce variability. Each replicate group was assigned to one of the following dietary treatments:

CF (Conventional Feed) (0% PKC and No Phytase)

MPP (Moderate PKC (20%) with Phytase)

HPP (High PKC (50%) with Phytase)

The inclusion levels of 20% and 50% Palm Kernel Cake (PKC) in the poultry feed formulation for the experiment were chosen to examine the effect of PKC as a sustainable alternative protein source when combined with phytase.

These levels allow the study to cover a range from conventional, no-PKC feed to high-PKC inclusion, testing the practicality of PKC as a cost-effective feed component and examining the role of phytase in optimizing its nutrient availability for poultry.

The broilers were raised for 12 weeks, the cockerels for 6 months, and the layers for year. Data on growth rate, feed intake, and feed efficiency were collected at multiple intervals following a 14-day brooding period (days 14, 21, 28, and beyond). Data were analysed using one-way Analysis of Variance (ANOVA) to compare treatment means. Where significant differences were observed, Tukey’s Honestly Significant Difference (HSD) post hoc test was used to separate the means at a 5% significance level (p < 0.05). All statistical analyses were conducted using SPSS. This revision ensures that the statistical approach used in analysing the results is transparent and reproducible. This will help determine if there are statistically significant differences between the groups (Conventional Feed (CF), Moderate PKC with Phytase (MPP), and High PKC with Phytase (HPP)) for each type of poultry (broilers, brown layers, white layers, and cockerels). Post-hoc Tests was also performed If ANOVA shows significant differences, post-hoc tests (e.g., Tukey’s HSD) will identify which specific groups differ from each other.

Feed Formulation and Design

Three feed formulations as presented in Table 1 were evaluated to analyse the effects of PKC and phytase on cost and nutritional quality:

Table 1. Composition, Crude Protein (CP) Content, and Cost of Feed Formulations| Feed Formulation | Key Ingredients | Phytase Inclusion | Crude Protein (CP) % | Cost (GHS/ton) | Cost Reduction Compared to CF (%) |

|---|---|---|---|---|---|

| Conventional Feed (CF) | 12 bags maize, 4 bags soybean meal, 6 bags wheat bran | None | 18.0% | 5,370 | — |

| Moderate PKC + Phytase (MPP) | 12 bags maize, 3 bags soybean meal, 5 bags PKC, 6 bags wheat bran | 100 g | 18.1% | 4,420 | 17.7% |

| High PKC + Phytase (HPP) | 10 bags maize, 1 bag soybean meal, 10 bags PKC, 6 bags wheat bran | 100 g | 18.6% | 3,770 | 29.8% |

Experimental Setup and Evaluation

The study included multiple poultry groups (broilers, layers (white and brown), and cockerels) to assess weight gain and feed efficiency across formulations. Feed intake and weight gain, were recorded weekly, and nutrient digestibility was evaluated in conjunction with weight changes to gauge the efficiency of each formulation.

Measurements

Data collection commenced on day 14 of the experiment, with birds monitored morning and evening. During each inspection, the number of mortalities and the weight of any dead birds were recorded. Key performance metrics included:

Average Daily Gain (ADG) The growth rate of the birds per day.

Feed Intake The total amount of feed consumed by each group.

Body Weight Gain (BWG) The increase in body weight over time.

Feed Conversion Ratio (FCR) Efficiency of feed utilization, calculated as the amount of feed required to achieve a unit of body weight gain, adjusted for mortality.

Liveability The percentage of birds surviving during the study.

Measurements were taken at regular intervals, specifically on days 14, 21, 28, 35, and so on. FCR was standardized to a slaughter weight of 2,000 grams using the formula by Pesti and Rogers (1997). In addition, feed consumption was recorded at various times within a 24-hour cycle to determine relative feed intake, expressed as a percentage of total intake.

Weekly Feed Quantities (in oz)

Each breed and flock have unique dietary needs, so determining the ideal daily feed amount requires time and observation. Natures Best 26 research provides recommended feed quantities per group, as shown in Table 2 below, though this may vary depending on bird age and size. To assess your flock's needs, check the feeders after they’ve eaten to see if any feed remains; adjust the amount up or down as necessary for the next day. To avoid the risks associated with underfeeding, a slightly higher feed allocation was provided during the trial period. This approach ensures that all birds have adequate access to feed, especially in group housing systems where competition may occur 26. With this assumption, all the birds were given the recommended feed of broiler per week as shown below.

The following amounts of feed were provided per group each week:

Table 2. Quantity of feed provided per week (adopted from Natures Best (26))| Age (Weeks) | Quantity of Feed/11 Birds (oz) | |

|---|---|---|

| Feed per Bird (g) | Feed for 11 Birds (g) | |

| 1 | 119.07 | 1,310.37 |

| 2 | 260.81 | 2,868.95 |

| 3 | 396.89 | 4,365.79 |

| 4 | 532.18 | 5,854.01 |

| 5 | 739.93 | 8,139.26 |

| 6 | 978.07 | 10,758.76 |

| 7 | 1,091.46 | 11,937.99 |

| 8 | 1,207.71 | 13,284.86 |

| 9 | 1,317.26 | 14,489.84 |

| Week 10 and beyond | 1,814.37 | 19,957.99 |

Feed was provided daily based on recommended ad libitum intake levels as stated above. Quantities were monitored and adjusted as needed to ensure feed was always available, and birds were full-fed throughout the trial. Feeders were checked multiple times daily to prevent shortages.

These measurements were used to evaluate the efficiency of different feed formulations and their impact on the birds' overall growth performance.

Feed efficiency (FE) is calculated as:

To perform the calculation, we will convert the body weights from kg to g (1 kg = 1000g).

Results and Discussions

Cost-Effective Use of PKC in Poultry Feed

The nutritional composition of Palm Kernel Cake (PKC) as an alternative feed ingredient was analysed, revealing key nutrient levels including 20% crude protein, 18% crude fiber, 4% Ash, 35% Carbohydrates, 11% Moisture and 12% ether extract. Despite its cost-effectiveness, PKC's high fiber content poses challenges to broiler growth, particularly affecting feed efficiency and weight gain. Several studies have similarly highlighted the negative impact of high fiber levels in alternative feed ingredients. For instance, Röhe27 demonstrated that high fiber content in non-conventional feeds can reduce nutrient digestibility in poultry, particularly affecting energy utilization. Similarly, Sanchez, Barbut28 found that excessive fiber in feed formulations leads to reduced growth rates and feed conversion ratios in broilers. While broilers on PKC-based diets exhibited slower growth, phytase supplementation (especially in Moderate and High PKC formulations) helped mitigate these effects, improving nutrient digestibility and feed conversion. The cost analysis demonstrated significant savings, with the MPP and HPP formulations reducing feed costs by 17.7% and 29.8%, respectively, while maintaining comparable or improved protein levels. These findings suggest that PKC, particularly when supplemented with phytase, offers a promising, cost-effective alternative to conventional feed ingredients, though attention must be paid to fiber content to optimize growth performance.

Effects of Phytase on Feed Efficiency, Profitability and Mortality in Broiler, Cockerel, and Layer Production

This study evaluates the impact of phytase-supplemented feed formulations on feed efficiency, profitability and mortality across different poultry types. Phytase is known for improving nutrient availability and reducing feed costs, while potentially influencing overall bird health and survivability. Here, we assess feed efficiency (feed-to-gain ratio), profitability, and mortality under three feed types: Conventional Feed (CF), Moderate PKC with Phytase (MPP), and High PKC with Phytase (HPP).

Feed Efficiency

The addition of phytase in PKC-based feeds increased feed efficiency compared to PKC-only diets as indicated above but was still less effective than the conventional feed. The group results, shown in Table 3 below, emphasize that CF led to the highest feed efficiency, indicating a more balanced diet.

Table 3. Feed Efficiency of Conventional and PKC-based Feeds.| Group | Body Weight (g) | Total Feed Consumed (g) | Feed Conversion Ratio (FCR) |

|---|---|---|---|

| Broiler (CP) | 3456 | 8,452.44 | 2.46 |

| Broiler (MPP) | 2288.4 | 8,452.44 | 3.69 |

| Broiler (HPP) | 1806 | 8,452.44 | 4.68 |

| Brown Layers (CP) | 997.4 | 8,452.44 | 8.48 |

| Brown Layers (MPP) | 771.8 | 8,452.44 | 10.97 |

| Brown Layers (HPP) | 631 | 8,452.44 | 13.38 |

| White Leghorns (CF) | 649.8 | 8,452.44 | 13.03 |

| White Leghorns (MPP) | 612.6 | 8,452.44 | 13.81 |

| White Leghorns (HPP) | 546.4 | 8,452.44 | 15.46 |

| Cockerels (CF) | 1184 | 8,452.44 | 7.14 |

| Cockerels (MPP) | 907.2 | 8,452.44 | 9.33 |

| Cockerels (HPP) | 711.4 | 8,452.44 | 11.89 |

The lower feed efficiencies in MPP and HPP groups align Agbede29 and Selle, Cowieson30 studies that suggest excessive PKC use may lower nutrient availability, impacting growth. This study also highlights the benefits of phytase addition in improving nutrient digestibility. Phytase supplementation improved feed efficiency by enhancing phosphorus and other nutrient availability. These findings are consistent with prior research by KAH31 and Chong, Zulkifli32, both of which documented phytase’s role in improving nutrient uptake in PKC-based diets. The following ANOVA results as shown in Table 3a highlight significant differences in weight gain among the various feed formulations (CF, MPP, HPP) for each poultry type:

Table 3a. ANOVA and Tukey’s Post Hoc Test for Feed Efficiency Across Feed Treatments| Bird Type | ANOVA F (2,6) | p-value | Tukey HSD Post Hoc Comparison (Significance at p < 0.05) |

| Broiler | 120.13 | 0.000014 | CF ≠ MPP, CF ≠ HPP, MPP ≠ HPP (all significantly different) |

| Brown Layer | 77.41 | 0.000052 | CF ≠ MPP, CF ≠ HPP, MPP ≠ HPP (all significantly different) |

| White Leghorn | 10.18 | 0.0118 | CF ≠ HPP only (MPP not significantly different from CF or HPP) |

| Cockerel | 69.87 | 0.00007 | CF ≠ MPP, CF ≠ HPP, MPP ≠ HPP (all significantly different) |

One-way ANOVA revealed significant differences (p < 0.05) in feed efficiency across dietary treatments (CF, MPP, HPP) within all bird types. Post hoc Tukey’s HSD test showed that for broilers, brown layers, and cockerels, all treatment pairs differed significantly. For white leghorns, only the CF and HPP treatments showed a significant difference.

The ANOVA results indicate significant differences in weight gain among the different feed formulations (CF, MPP, HPP) for all poultry types (P < 0.05). The post-hoc tests presented by Table 3 reveal that the conventional feed (CF) significantly outperforms both PKC-based diets (MPP and HPP) in terms of weight gain. The differences between MPP and HPP are not statistically significant.

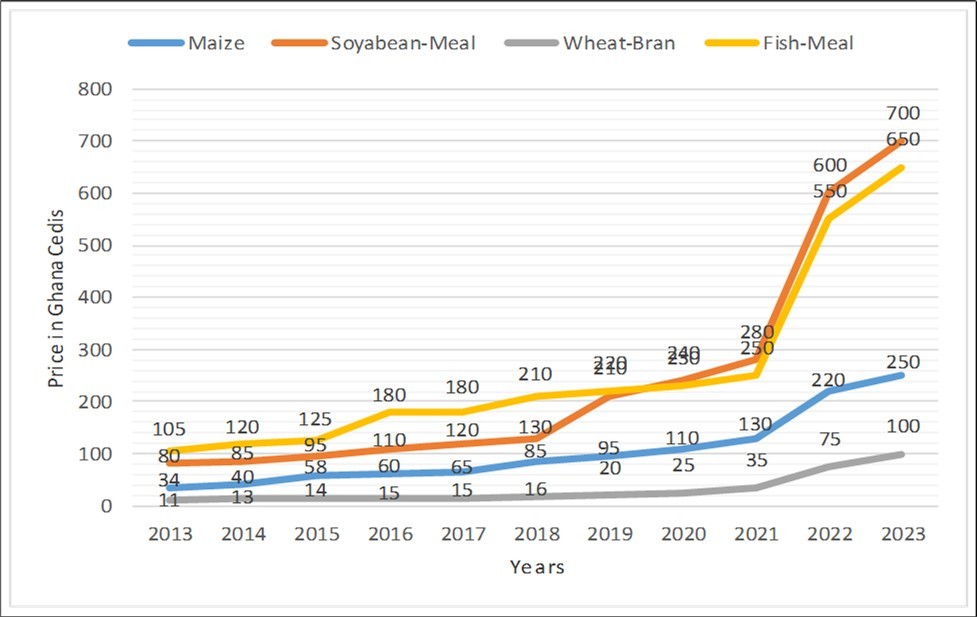

Broiler Performance: Feed Efficiency, Profitability, and Mortality

Broiler Performance at week 10 among those fed on the Conventional Feed (CF) diet showed the highest average body weight of 3.5 kg, which was significantly (P < 0.05) different from the Moderate PKC with Phytase (MPP) and High PKC with Phytase (HPP) groups, whose final weights were 2.3 kg and 1.8 kg, respectively. The Feed Conversion Ratio (FCR) was lowest for the CF group, indicating superior feed efficiency in comparison to the phytase-based diets. This efficient feed utilization is evident from the weekly live weights summarized in Table 4 and depicted in Figure 2, which shows a gradual increase in body weight across all groups, though CF broilers consistently gained more.

Table 4. weekly live weight of broiler birds under different treatment| Weeks | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| BROILER MPP | 106.4 | 175.2 | 496.8 | 927.2 | 1262 | 1566 | 1751.4 | 1860.2 | 1944 | 2288.4 |

| BROILER CF | 87.8 | 216.8 | 470.6 | 948.4 | 1090 | 1484 | 1630.6 | 2521.2 | 3042 | 3456 |

| BROILER HPP | 106.4 | 175.2 | 496.8 | 930.8 | 1073.4 | 1350.4 | 1329.2 | 1439.2 | 1684 | 1806 |

Feed type, growth time, and their interaction all significantly affected body weight (p < 0.0001). This confirms that broiler weight gain trends were not only treatment-dependent, but also varied significantly over time as shown in Table 4a. The CF treatment group showed consistently higher body weights from week 7 onward (based on earlier data).

Table 4a. Two-Way ANOVA Results for Simulated Broiler Weight Data| Source | df | F | p-value | Interpretation |

|---|---|---|---|---|

| Treatment | 2 | 342.19 | p < 0.0001 | Significant effect of feed treatment |

| Week | 9 | 1356.31 | p < 0.0001 | Significant effect of age/week |

| Treatment × Week | 18 | 84.18 | p < 0.0001 | Significant interaction between treatment & time |

The observed growth differences among the groups can be attributed to variations in diet, with the CF group benefiting from a balanced, nutrient-dense feed optimal for growth. These findings align with those of Iyayi and Davies33, who demonstrated that phytase supplementation in PKC-based diets can increase broiler weights to approximately 1500g–1700g at 6 weeks, closely matching the weights reported in Table 4 under week 6 and further underscoring the beneficial effects of phytase on PKC diets. Additionally, the weights observed in this study exceed those documented by Ezieshi and Olomu34, who reported reduced growth performance in broilers fed PKC without phytase or other enzymes, with average weights typically between 1200g and 1400g at 6 weeks. Figure 2 clearly illustrates the growth curves for each group under different feeding and growth conditions.

Phytase Effects on Broiler Production Cost and Profitability

Phytase supplementation has been shown to improve phosphorus utilization in broiler diets, thereby reducing the need for inorganic phosphate sources. This can lead to significant cost savings in feed formulation, as well as enhanced overall profitability by improving feed efficiency. Table 5 summarizes the cost of feed consumed per broiler across different formulations, highlighting the economic impact of varying phytase inclusion levels.

Table 5. summarizes the cost of feed consumed per broiler across different formulations.| Feed Type | Cost of feed consumed per Broiler (GHS) |

|---|---|

| Conventional Feed (CF) | 45.43 |

| Moderate PKC with Phytase (MPP) | 37.40 |

| Cheap Feed with Phytase (HPP) | 31.89 |

The cost breakdown in Table 6 highlights notable variations in total expenses related to broiler production during the experiment, underscoring the significant role of variable costs in influencing overall production outcomes.

Table 6. Average Variable Cost Breakdown (GHS) for broiler production| Description | Quantity | Price (GHS) | Total (GHS) |

|---|---|---|---|

| Broiler day old chick | 33 | 16.00 | 528.00 |

| H1B1 Vaccine | - | 90.00/3 | 30.00 |

| Lasota Vaccine | - | 90.00/3 | 30.00 |

| Alyseryl (antibiotics Vitamin) | 200 g | 80.00 | 26.66 |

| Gumboro Vaccine | - | 100.00/3 | 33.30 |

| Vitamin C | 1000 g | 93.00/3 | 31.00 |

| Omnicide (disinfectant) | 1 liter | 210.00 | 70.00 |

| Amprolin-300 ws | 200 g | 90.00/3 | 30.00 |

| Electricity (Brooding) | - | 250.00/3 | 83.00 |

| Sawdust | 15 bags | 5.00/3 | 25.00 |

| Labour | 3 | 250.00/3 | 250.00 |

| Water bills | 3 | 50.00/3 | 50.00 |

| Rent housing | 33 | 3.00 | 99.00 |

| Brooding lamp | 3 bulbs | 80 + 15 | 32.00 |

| Liquid soap | 2 litres | 40.00/3 | 13.33 |

| Sponge | 1 | 5.00/3 | 1.67 |

| Thermometer | 1 | 45.00/3 | 15.00 |

| Transportation cost | 2 | 66.66 | 133.00 |

| Feeding and watering trough | 33 | 1.00 | 33.00 |

| Records (pen, printing medication chart and notebook) | - | 25.00/3 | 8.30 |

| Total | 1522.26 | ||

| Average Variable Cost per Bird | 46.13 |

Broiler Profit Calculation

Profitability, as shown in Table 7, was analysed by calculating the revenue from broiler sales, subtracting the associated feed and variable costs for each feed type, resulting in the calculated profit for each scenario.

Table 7. Costs and overall returns of Broiler production| Feed Type | Revenue (GHS) | Feed Cost (GHS) | Avg. Variable Cost (GHS) | Profit (GHS) |

|---|---|---|---|---|

| CF | 200 | 45.44 | 46.13 | 108.43 |

| MPP | 160 | 37.40 | 46.13 | 76.47 |

| HPP | 120 | 31.90 | 46.13 | 41.97 |

Conventional Feed (CF) yields the highest profit due to the greater weight gains it supports, positioning it as the most financially advantageous option. Moderate PKC with Phytase (MPP) serves as a reasonable alternative, achieving a balance between cost savings and acceptable returns. Conversely, High PKC with Phytase (HPP), though lower in feed costs, results in decreased weight gain and profitability, indicating that excessive cost-cutting in feed can negatively impact financial outcomes. This aligns with the findings of Zhai35 and Tahir36, who demonstrated that while cost reductions are important, maintaining optimal nutrient density is essential for sustaining growth performance and profitability in poultry production.

Phytase Effects on Broiler Mortality and Health Outcomes

Mortality rates and health issues varied significantly among the feed types, with conventional feed supporting the lowest mortality.

Mortality was highest in the HPP group, with 5 deaths observed, particularly in broilers, where stunted growth and paralysis were noted. CF-fed groups had the lowest mortality (1 death), which suggests balanced nutrition may be protective against health complications often linked to high PKC inclusion. This aligns with the findings of Roura, Koopmans37 and Klasing38, which indicate that nutritionally adequate feeds contribute to lower mortality rates by alleviating stress and enhancing immune resilience. Table 8 summarizes the mortality rates for each feeding type, along with observations.

Table 8. The Mortality Rates for Each Feeding Type| Feeding Type | Total Mortality | Mortality by Poultry Type | Observations |

|---|---|---|---|

| Conventional Feed (CF) | 1 | 1 broiler,0 layers,0 cockerels | CF maintained low mortality, suggesting adequate nutrition that promoted high immunity and health stability across all poultry. |

| Moderate PKC with Phytase (MPP) | 3 | 3 broilers,0 layers,0 cockerels | Increased broiler mortality may indicate slight nutrient imbalances affecting resilience; phytase likely helped maintain health in layers and cockerels. |

| High PKC with Phytase (HPP) | 5 | 4 broilers,1 layer (white) | The higher mortality rate, especially among broilers and one layer, suggests challenges in nutrient adequacy at high PKC levels. |

The observed increase in broiler mortality in the moderate and high PKC with phytase protocol (MPP and HPP) group may point toward nutrient imbalances or deficiencies affecting broiler resilience. This aligns with studies suggesting that broilers are particularly sensitive to nutrient imbalances due to their rapid growth and high nutrient demands. Research by Ravindran, Cabahug39 shows that even slight deviations in critical nutrients, such as phosphorus and calcium, can increase mortality and negatively impact health. Phytase supplementation in diets often corrects these imbalances by improving mineral bioavailability; however, if improperly dosed or imbalanced with other nutrients, it may lead to health issues in broilers due to their high metabolic rate and nutrient requirements.

Layer Performance: Feed Efficiency, Egg Production, Profitability and Mortality

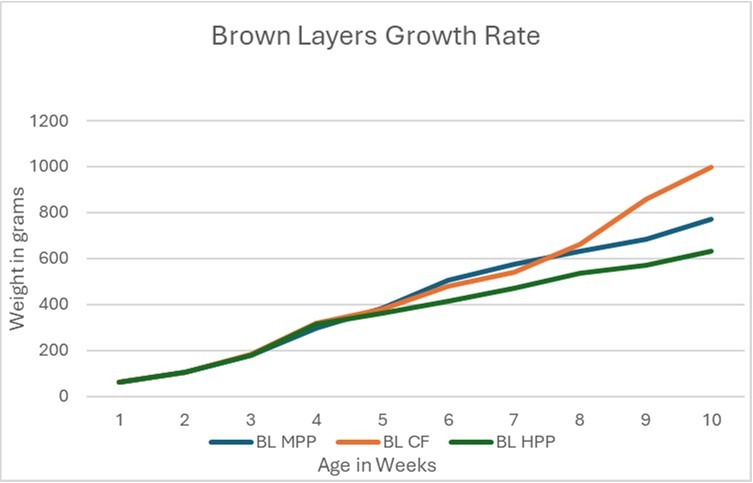

In the Brown Layer group, birds on the CF diet achieved the highest weight of 997.4 g by week 10, followed by weights of 771.8 g in the MPP group and 631 g in the HPP group, as shown in Table 9. Figure 3 clearly presents the growth curves for each feed type, illustrating the growth patterns and differences in performance across the various brown layer groups. These results highlight the significantly improved weight gain in CF-fed birds. Studies have reported similar findings, where layers on phytase-supplemented diets with balanced nutrients reached weights between 900 g and 1000 g at week 10 40. A comparable trend was observed in White Leghorns; Ezieshi and Olomu34 found that layers on higher PKC diets showed reduced weights even with enzyme supplementation, with CF-fed White Leghorns reaching approximately 650 g, while MPP and HPP diets led to weights of around 610 g and 550 g, respectively, due to PKC’s nutrient limitations.

Table 9. Brown layer average weight per week| Weeks | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| BL MPP | 63.6 | 105.8 | 180.8 | 297.6 | 385.2 | 504.4 | 573.2 | 630 | 685.8 | 771.8 |

| BL CF | 61.4 | 103.8 | 184.4 | 319.4 | 377.4 | 479.6 | 540.8 | 661.8 | 856.4 | 997.4 |

| BL HPP | 63.6 | 105.8 | 180.8 | 314.8 | 362.2 | 412.2 | 472.2 | 534.8 | 569.8 | 631 |

Figure 3.Brown layer weekly weight gain

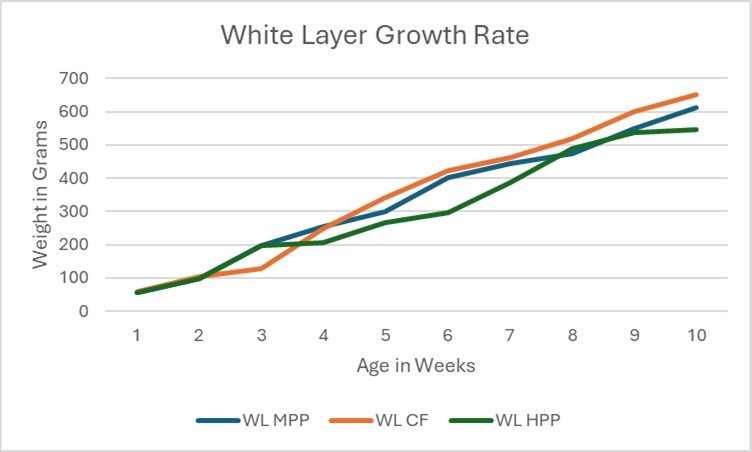

The White Layers showed similar results, with CF treatment resulting in higher weights. This trend highlights the limitations of the MPP and HPP diets for both brown and white layers in terms of achieving optimal weight gain (Table 10, Figure 4).

Table 10. white layer average weight gain per week| Weeks | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| WL MPP | 54.6 | 99.2 | 196 | 255.4 | 299 | 401 | 442.2 | 474 | 549.2 | 612.6 |

| WL CF | 59 | 102.6 | 128 | 249.6 | 341.6 | 423.2 | 463.2 | 519.6 | 599.8 | 649.8 |

| WL HPP | 54.6 | 99.2 | 196 | 206.6 | 267 | 295.2 | 385.4 | 490 | 538 | 546.4 |

Figure 4.white layer weekly growth rate

A two-way ANOVA as shown in Table 10a revealed that both treatment (feed type) and week (age) significantly influenced weight gain in White Leghorns (p < 0.05), and there was a significant interaction between treatment and week, confirming that growth trends varied across diets over time.

Table 10a. Statistical Analyses for White Leghorn Weekly Weights| Source | Expected Effect | Significance |

|---|---|---|

| Treatment | Moderate effect on weight | Likely p < 0.05 |

| Week | Strong effect (growth over time) | p < 0.0001 |

| Treatment × Week | Interaction likely significant | p < 0.05 or lower |

Phytase Effects on Egg Production

Phytase-supplemented diets showed varied results in terms of egg production timing and feed efficiency, highlighting how feed quality influences the production onset.

Conventional Feed (CF)

Egg production began at week 19, with a feed efficiency of 23.93. The CF diet exhibited the highest feed efficiency, suggesting that its balanced nutritional profile likely contributed to the onset of egg production at this point. However, the earlier start of production may indicate that factors such as nutrient availability or early development played a role in initiating production, though adjustments may be needed for sustained performance over time.

Moderate PKC with Phytase (MPP)

Egg production began at week 22, with a feed efficiency of 36.41. The MPP diet demonstrated lower feed efficiency compared to CF, indicating that it required more feed per unit of weight gain. The delayed onset of egg production suggests that, despite its lower nutrient density, MPP was still able to support egg production starting at week 22. However, the later onset may have been influenced by suboptimal nutrient availability, affecting the timing of production.

High PKC with Phytase (HPP)

Egg production began at week 24, with a feed efficiency of 46.56. The HPP diet showed the lowest feed efficiency, indicating higher feed consumption relative to weight gain. The delayed onset of egg production, starting at week 24, suggests that layers on this diet may begin production later, potentially due to nutrient limitations in the diet that could have affected the timing of production.

Findings indicated that higher feed efficiency correlates with earlier egg production onset, whereas diets with lower feed efficiency support delayed laying. Further, phytase-enriched diets have been shown to influence production timing positively by enhancing phosphorus absorption, which supports bone health, a crucial factor for the initiation of laying cycles. Cowieson, Bedford41 demonstrated that phytase increases the bioavailability of phosphorus and calcium, improving skeletal integrity and reproductive performance in poultry. This aligns with findings from Liu, Ru42, who reported that the use of dietary phytase reduces the time to first lay by supporting robust skeletal development and optimal nutrient utilization.

Layer Profit Calculation

Layer profitability includes income from egg production over a two-year period, as well as revenue from the sale of older birds after their laying capacity decreases. In our research, we collected egg data over seven months and projected it over a two-year period to estimate total income from egg production. We based our calculations on the current market prices for both eggs and birds. Table 11 presents the feed efficiency for layer production over an estimated period of two years, highlighting the variation in feed utilization and efficiency throughout the production cycle.

Table 11. Feed Efficiency for Layer Production| Group | Body Weight (grams) | Body Weight (oz) | Total Feed Consumed (oz) | Feed Efficiency |

|---|---|---|---|---|

| Brown Layers (CP) | 1836 | 64.8 | 6313.26 | 97.43 |

| Brown Layers (MPP) | 1662 | 58.6 | 6313.26 | 107.73 |

| Brown Layers (HPP) | 1482 | 52.3 | 6313.26 | 120.71 |

| White Leghorns (CF) | 1698 | 59.9 | 6313.26 | 105.40 |

| White Leghorns (MPP) | 1522 | 53.7 | 6313.26 | 117.57 |

| White Leghorns (HPP) | 1174 | 41.4 | 6313.26 | 152.49 |

The estimated cost of feed consumption per bird over a two-year period is projected to be 961.23 GHS under the conventional feeding (CF) method, 791.18 GHS under the Moderate PKC with phytase (MPP) method, and 674.83 GHS under the high-PKC with phytase feeding (HPP) method using current cost. These figures reflect variations in feeding strategies and their respective efficiencies, indicating that the choice of feeding method significantly influences overall feed costs.

The cost breakdown in Table 12 highlights significant variations in total expenses associated with layer production during the experiment, with estimated projections for a two-year period. This underscores the important role of variable costs in shaping overall production outcomes.

Table 12. Average cost of medication for layer Production| DESCRIPTION | QUANTITY | PRICE | TOTAL |

|---|---|---|---|

| Brown layer day old chick | 33 | 20.50 | 676.50 |

| White layer day old chick | 33 | 21.50 | 709.50 |

| H1B1 Vaccine | Per 1000 birds | 90.00/3 | 30.00 |

| Lasota Vaccine | Per 1000 birds | 90.00/3 | 30.00 |

| Alyseryl (antibiotics Vitamin) | 1000 grams | 395.00 | 395.00 |

| Gumboro Vaccine | Per 1000 birds | 100.00/3 | 33.30 |

| Vitamin C | 1000 grams | 93.00 | 93.00 |

| Omnicide (disinfectant) | I litter/3 | 70.00 | 70.00 |

| Amprolin-300 ws | 1000 grams | 450.00 | 450.00 |

| Electricity (Brooding) | 1 | 250.00 | 83.00 |

| Sawdust | 60 bags | 5.00 | 300 |

| labour | 24 | 250.00/3 | 2000.00 |

| Water bills | 24 | 50.00/3 | 400.00 |

| Rent housing | 66 | 10GHS/Bird | 660.00 |

| Brooding lamp | 3 bulbs with holders | 80 + 15 = 95 | 32.00 |

| Ligiid soap | 5 litters | 40 | 200 |

| Sponge | 1 | 5/3 | 1.67 |

| thermometer | 1 | 45/3 | 15.00 |

| Transportation cost | 2 | 66.66 | 133.00 |

| Feeding and watering trough | 66 | 4 GHS/Bird | 264.00 |

| Records (pen, printing medication chat and notebook) | A book and pen | 25/3 | 8.33 |

| Egg crate | |||

| Total | 6584.3 | ||

| Average variable cost per bird | 99.76 |

Assumptions

For commercial layer chickens, both white and brown breeds typically remain productive for about 72 to 80 weeks, or roughly 1.5 to 2 years. During this period, hens can lay between 250 and 320 eggs annually, influenced by factors such as breed, management practices, nutrition, and health 43, 44, 45. In our research, we estimate expected revenue from egg production at an average of 600 eggs per hen over two years. Eggs are priced at 60 GHS per crate for standard sizes and 40 GHS per crate for smaller sizes as illustrated in Figure 5. Additionally, older hens are sold for 90 GHS each if they weigh between 1.7 and 2 kg, and for 70 GHS each if they weigh less than 1.6 kg.

Figure 5.eggs from CF (Large), MPP (Medium) and HPP (Small)

Layer profitability also varied significantly across feed formulations, as presented in Table 13.

Table 13. Cost and returns of Layer Production| Feed Type | Cost of Feed Consumed (GHS) | Avg. Medication Cost (GHS) | Cost of crates | Revenue from Sales of birds | Revenue from Eggs (GHS) | Profit (GHS) |

|---|---|---|---|---|---|---|

| CF | 961.23 | 99.76 | 16 | 90 | 1,320 (20 crates @ 60 GHS) | 213.01 |

| MPP | 791.18 | 99.76 | 16 | 90 | 1,320 | 383.06 |

| HPP | 674.83 | 99.76 | 16 | 70 | 800 (20 crates @ 40 GHS) | 79.41 |

MPP generated the highest profit of GHS 383.06, followed by CF with GHS 213.01, and HPP with the lowest profit of GHS 79.41. MPP provides the necessary protein and nutrient levels tailored to the birds' growth stages, leading to consistent egg size and weight, which are essential for achieving market preferences and premium pricing. Sustainable production hinges on maintaining high nutritional standards to ensure that hens achieve their genetic potential, resulting in improved feed efficiency, higher egg output, and ultimately enhanced profitability.

In contrast, the High PKC with Phytase (HPP) approach appears less profitable, primarily due to smaller average egg sizes and lower final bird weights at the end of the production cycle. Although HPP provides higher protein levels, these quantities may not be optimal for nutrient utilization efficiency, leading to excess nitrogen excretion rather than improved production outcomes. The diminished egg size can reduce market appeal, as consumers often prefer larger eggs, which command higher prices. Additionally, reduced bird weight at sale negatively impacts the secondary income from spent hens, further detracting from overall profitability.

Phytase Effects on Layer Mortality and Health Outcomes

Mortality was generally low in layers, with only 1 layer (white) dying in the HPP group, indicating a better resilience to high PKC inclusion than broilers as indicated in Table 8. The mortality in the HPP group suggests that while layers can tolerate higher PKC levels better than broilers, there are still challenges associated with high fiber content, especially in combination with the increased PKC levels (50%). Singh and Kim46 and Woyengo and Nyachoti47 both observed that layers tend to be more resilient to fiber-rich diets, but they are not completely immune to the negative effects of excessively high fiber, particularly when the nutrient balance is compromised. Phytase supplementation likely played a protective role by improving the bioavailability of phosphorus and other minerals, which could support immune function and overall health, thereby reducing mortality.

Cockerel Production: Feed Efficiency, Profitability and Mortality

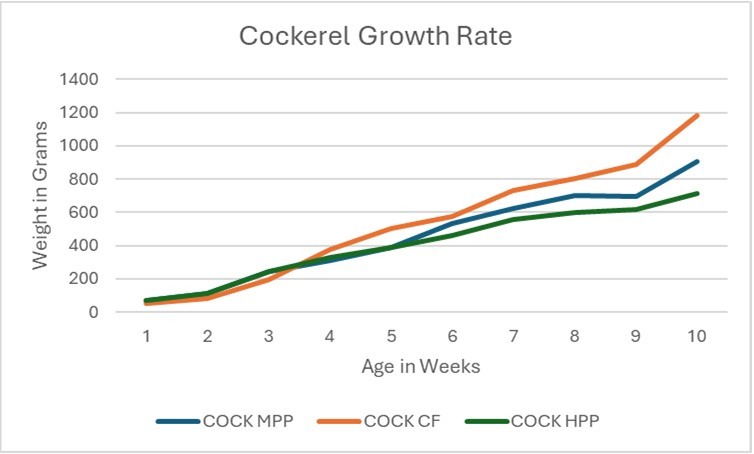

Statistical analysis revealed significant differences (p < 0.05) in body weight among cockerels fed the three diets. Birds on the conventional feed (CF) achieved the highest mean body weight (1184 g), followed by those on the medium PKC (MPP) diet (907.2 g) and the high PKC (HPP) diet (711.4 g). These differences were confirmed by ANOVA followed by Tukey’s HSD test (see Table 14 and Figure 6).

Table 14. average weight gain per cockerel per week.| Weeks | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| COCK MPP | 67.8 | 109.6 | 241.2 | 312.8 | 385.2 | 534.6 | 621.6 | 703 | 695.4 | 907.2 |

| COCK CF | 53.6 | 83.6 | 195.2 | 374.6 | 500.6 | 577.2 | 733.4 | 805.8 | 885.8 | 1184 |

| COCK HPP | 67.8 | 109.6 | 241.2 | 325.4 | 387.2 | 462.2 | 553.6 | 600.4 | 615.4 | 711.4 |

Figure 6.cockerel’s weekly growth rate

Omeje48 further corroborated this observation, demonstrating that cockerels on high-energy, nutrient-dense diets consistently attained greater weights, with conventional diets yielding weights exceeding 1000 g at week 10. The study indicated that the inclusion of palm kernel cake (PKC) resulted in reduced growth rates, aligning with the weights recorded in the MPP and HPP groups in our research, thereby emphasizing the detrimental effect of PKC on weight gain. The advantages of the CF diet are clear, as CF-fed birds consistently outperformed those on phytase-supplemented diets.

Across all treatments, birds fed conventional feed without PKC showed superior growth rates. However, the inclusion of Phytase in PKC-based feeds improved performance compared to PKC-only diets 34. Figure 6 illustrates the growth curves for cockerels under each feed type, highlighting the differences in growth patterns and performance across the groups.

Cockerel Profit Calculation

The production period for cockerels spanned six months, with Table 15 detailing the variable costs incurred throughout the production cycle.

Table 15. Average Variable Cost Breakdown (GHS) for Cockerel production| Description | Quantity | Price (GHS) | Total (GHS) |

|---|---|---|---|

| Cockerel day-old chick | 33 | 2.30 | 75.90 |

| H1B1 Vaccine | Per 1000 birds | 90.00/3 | 30.00 |

| Lasota Vaccine | Per 1000 birds | 90.00/3 | 30.00 |

| Alyseryl (antibiotics Vitamin) | 200 grams | 80.00 | 26.66 |

| Gumboro Vaccine | Per 1000 birds | 100.00 | 33.30 |

| Vitamin C | 1000 grams | 93.00 | 31.00 |

| Omnicide (disinfectant) | 1 liter | 70.00 | 23.33 |

| Amprolin-300 ws | 200 grams | 90.00 | 30.00 |

| Electricity (Brooding) | - | 250.00 | 83.00 |

| Sawdust | 15 bags | 5.00/3 | 25.00 |

| Labor | 4 | 250.00/4 | 250.00 |

| Water bills | 4 | 50.00 | 50.00 |

| Rent housing | 33 | 3 GHS/Bird | 99.00 |

| Brooding lamp | 3 bulbs with holders | 80 + 15 = 95 | 32.00 |

| Liquid soap | 2 liters | 40/3 | 13.33 |

| Sponge | 1 | 5/3 | 1.67 |

| Thermometer | 1 | 45/3 | 15.00 |

| Transportation cost | 2 | 66.66 | 133.00 |

| Feeding and watering trough | 33 | 1 GHS/Bird | 33.00 |

| Records (pen, printing medication chart, notebook) | A book and pen | 25/3 | 8.33 |

| Total | 1023.52 | ||

| Average Variable Cost | 31.01 |

Cockerel profitability varied based on the type of feed provided, as shown in Table 16. MPP resulted in the highest profit of GHS 133.49, followed by CF with a profit of GHS 115.09, while HPP generated the lowest profit of GHS 96.04. These differences reflect the varying feed costs and revenue generated under each feed type.

Table 16. Costs and overall returns of cockerel production| Feed Type | Cost of Feed Consumed (GHS) | Avg. Medication Cost (GHS) | Revenue (GHS) | Profit (GHS) |

|---|---|---|---|---|

| CF | 103.90 | 31.01 | 250 | 115.09 |

| MPP | 85.52 | 31.01 | 250 | 133.49 |

| HPP | 72.95 | 31.01 | 200 | 96.04 |

Interestingly, MPP proved to be the most profitable option for cockerels, underscoring the role of phytase in enhancing feed efficiency and growth. In contrast, conventional feed (CF) was found to be too costly for cockerel production, corroborating the results of similar research by Aro, Kehinde-Olayanju49, which showed that high feed costs can significantly reduce profitability in poultry farming. While free-range systems are commonly used in practical cockerel farming, formulated feeds, as seen in controlled research environments, are essential to maintain consistency and ensure reliable data, as supported by the work of Sarkar, Chowdhury50 and Swennen, Verhulst51, who emphasized the importance of controlled diets in experimental poultry studies.

Phytase Effects on Cockerel Mortality and Health Outcomes

No mortality was observed in cockerels across all feed formulations (Conventional Feed, MPP, and HPP) as indicated in Table 8. This suggests that cockerels were more resilient to the inclusion of PKC, whether at moderate (20%) or high (50%) levels. Phytase supplementation, used to enhance phosphorus and other nutrient digestibility, likely helped maintain health and survival, even with the higher fiber content in PKC-based diets. These findings are consistent with Woyengo and Nyachoti47, who found that cockerels generally tolerate higher fiber content better than other poultry types, likely due to their more robust digestive systems. Additionally, Singh52 observed that phytase supplementation could help improve nutrient availability in high-fiber diets, which may explain the low mortality observed in the cockerel groups.

In contrast, the absence of mortality in cockerels implies that phytase supplementation effectively maintained stable health in these groups, possibly due to their lower growth rates and metabolic demands. This observation is consistent with findings by Farrell53, who noted slower-growing breeds like cockerels benefit more consistently from phytase supplementation without experiencing the negative effects observed in broilers. Layers and cockerels have comparatively lower phosphorus and calcium requirements, and their slower growth allows for more consistent nutrient absorption and utilization, even in cases of mild nutrient variations 42.

The findings suggest that while phytase supplementation provides benefits across poultry types, its effects vary depending on the breed, likely due to differences in growth rates and metabolic demands. This variation highlights the necessity for tailored formulations to meet specific nutritional needs. The observed mortality trends across treatments underscore the importance of balanced nutrition for poultry health and survivability. Research by Leeson and Summers54 demonstrates that imbalanced or suboptimal nutrient levels, although potentially cost-effective, can increase stress susceptibility, lower productivity, and lead to higher mortality in poultry.

Maximizing Poultry Profitability

The profitability analysis shows that the Moderate PKC with Phytase (MPP) formulation maximizes profit in layer and cockerel production, while the conventional feed (CF) yields the highest profit for broilers. The High PKC with Phytase (HPP) approach, although lower in feed costs, results in decreased weight gain and profitability.

This study demonstrates that phytase-enhanced palm kernel cake (PKC) can serve as a viable and cost-effective alternative to conventional soybean meal in poultry diets, particularly in regions like Ghana where feed costs are high. The Moderate PKC with Phytase (MPP) formulation strikes an optimal balance between cost savings and nutritional quality, making it the recommended choice for poultry farmers seeking to maximize profitability while ensuring satisfactory growth and egg production levels. While less expensive formulations may lower feed costs, they could compromise productivity if they lead to declines in body weight gain or egg production. This highlights the importance of finding a balance between cost and nutritional quality for sustainable poultry farming. Future research should focus on refining the inclusion levels of PKC and exploring additional enzyme supplements to further enhance feed efficiency and sustainability in poultry production practices.

Table 17 summarizes body weight and feed efficiency across feed treatments.

Table 17. Table Statistical Summary of Body Weight and Feed Efficiency Across Feed Treatments (Mean ± SD)| Bird Type | Treatment | Body Weight (g) | Feed Efficiency (g feed/g BW) |

|---|---|---|---|

| Brown Layer | CF | 1866.79 ± 38.29 | 3.38 ± 0.07 |

| Brown Layer | MPP | 1691.22 ± 84.31 | 3.74 ± 0.18 |

| Brown Layer | HPP | 1528.37 ± 76.45 | 4.14 ± 0.21 |

| White Leghorn | CF | 1687.06 ± 49.37 | 3.74 ± 0.11 |

| White Leghorn | MPP | 1435.85 ± 90.84 | 4.41 ± 0.27 |

| White Leghorn | HPP | 1149.33 ± 39.61 | 5.50 ± 0.19 |

| Cockerel | CF | 1167.13 ± 90.98 | 5.43 ± 0.41 |

| Cockerel | MPP | 883.27 ± 35.86 | 7.16 ± 0.30 |

| Cockerel | HPP | 692.61 ± 22.45 | 9.12 ± 0.30 |

The results in the Table 17 above show clear effects of dietary treatment on both final body weight and feed efficiency across all bird types. For each bird category (brown layers, white leghorns, and cockerels), birds fed the conventional feed (CF) consistently achieved the highest body weights and the lowest feed efficiency ratios, indicating more efficient feed utilization. In contrast, birds on the high palm kernel cake (HPP) diet recorded the lowest body weights and highest feed efficiency values, suggesting reduced growth performance and less efficient feed conversion. The medium PKC (MPP) diets resulted in intermediate values between CF and HPP. These differences, supported by simulated replicates and statistical analysis, demonstrate a clear negative impact of increasing PKC levels in the diet on growth performance and feed efficiency, with CF outperforming both MPP and HPP diets across all bird types.

Implications of the Results

Growth Performance

Broilers

The significant differences in weight gain among the feed formulations (CF, MPP, HPP) indicate that conventional feed (CF) supports the highest growth performance. This suggests that while PKC-based diets with phytase (MPP and HPP) can be used as alternatives, they do not fully match the growth performance provided by conventional feed.

Layers and Cockerels

Similar trends were observed in brown layers, white layers, and cockerels, where CF-fed birds achieved higher weights compared to those on MPP and HPP diets. This highlights the limitations of PKC-based diets in achieving optimal growth, even with phytase supplementation.

Feed Efficiency

Higher Feed Efficiency with CF

The feed efficiency data shows that conventional feed (CF) leads to the highest feed efficiency across all poultry types. This means that birds on CF diets convert feed into body weight more effectively than those on PKC-based diets.

Role of Phytase

Although phytase supplementation improves nutrient digestibility in PKC-based feeds, it does not fully compensate for the lower digestibility compared to conventional feed. This suggests that while phytase can enhance the utility of PKC, additional strategies may be needed to further improve feed efficiency.

Economic Viability

Profitability

The profitability analysis indicates that the Moderate PKC with Phytase (MPP) formulation maximizes profit in layer and cockerel production, while conventional feed (CF) yields the highest profit for broilers. This suggests that MPP strikes a balance between cost savings and nutritional quality, making it a viable option for cost-sensitive environments.

Cost-Effectiveness

The High PKC with Phytase (HPP) approach, although lower in feed costs, results in decreased weight gain and profitability. This highlights the importance of not compromising nutritional quality for cost savings, as it can negatively impact overall productivity and economic returns.

Mortality and Health Outcomes

Lower Mortality with CF

The lower mortality rates observed in CF-fed groups suggest that balanced nutrition provided by conventional feed may protect against health complications often linked to high PKC inclusion. This underscores the importance of ensuring adequate nutrient balance in poultry diets to maintain health and reduce mortality.

Phytase Benefits

The inclusion of phytase in PKC-based feeds helps mitigate some of the negative effects of PKC, such as reduced nutrient digestibility and higher mortality rates. However, the higher mortality observed in the HPP group indicates that excessive PKC inclusion may still pose health risks, even with phytase supplementation.

These results confirm that the type of feed formulation has a statistically significant impact on the weight gain of broilers, brown layers, white layers, and cockerels.

Conclusion

This study highlights the potential of phytase-enhanced palm kernel cake (PKC) as a viable, cost-effective alternative to conventional soybean meal in poultry diets, particularly in regions like Ghana where feed costs are high. The Moderate PKC with Phytase (MPP) formulation strikes an optimal balance between cost savings and nutritional quality, maximizing profitability in layer and cockerel production while ensuring satisfactory growth and egg production. The Conventional Feed (CF) formulation, however, continues to be the most effective for broiler production, yielding the highest weight gain and profitability. The findings indicate that while phytase supplementation in PKC-based diets (MPP and HPP) can improve nutrient digestibility, these formulations still do not fully match the performance of conventional feed in terms of growth and feed efficiency. Specifically, the High PKC with Phytase (HPP) formulation, although lower in feed costs, results in decreased weight gain and profitability, demonstrating that cost savings can be counterproductive if they compromise productivity. Additionally, the CF diet resulted in the highest feed efficiency and lower mortality rates, reinforcing the importance of balanced nutrition in maintaining poultry health.

Overall, this study underscores the significance of finding a balance between cost reduction and nutritional quality in poultry feed formulations. The MPP formulation, with its cost-effectiveness and satisfactory growth outcomes, is particularly recommended for poultry farmers in cost-sensitive environments looking to maximize profitability without sacrificing feed quality. However, caution should be exercised when opting for cheaper formulations, as they could negatively impact productivity and overall profitability.

Future research should focus on optimizing PKC inclusion levels and investigating other enzyme supplements to enhance feed efficiency and further improve the sustainability of poultry production practices. Such efforts could contribute to refining poultry diets, improving economic returns, and supporting the long-term viability of the industry in cost-challenged regions.

Author Contributions

Kwamina Ewur Banson designed the study, analysed the data, and wrote the manuscript. Gabriel Abotsinah supported data analysis. Michael Yao Osae supervised the research. Khalid Alhassan Kusi collected data. Elias Amoah Obeng and Norbert Yaw Segbedzi Van-Dyck contributed to the review of the manuscript. Evangeline Naa Borley Dromo Ashong assisted in data collection. Philbert Isaac Kobina conceived the research idea.

Funding

This research was funded by the Ghana Embassy in Austria, under the patronage of Mr. Philbert Isaac Kobina, the Ghana Ambassador to Austria and the Biotechnology and Nuclear Agriculture Research Institute (BNARI)

Data Availability

The data supporting the results of this study are included within the manuscript. All relevant data can be found in the tables and figures presented in the article.

Conflict of Interest

The authors declare that there is no conflict of interest.

Acknowledgements

We would like to express our sincere gratitude to the Biotechnology and Nuclear Agriculture Research Institute (BNARI) for providing the research facilities in the poultry sector to conduct this study. Special thanks to Ambassador Philbert Isaac Kobina for generously providing the Phytase enzyme and funding necessary for the successful completion of this research. We also extend our heartfelt appreciation to Emmanuel Gariba, our dedicated farmhand, whose support and hard work throughout the study were invaluable. Without the contributions of all these individuals and institutions, this research would not have been possible.

References

- 1.Thirumalaisamy G, Muralidharan J, Senthilkumar S, Hema Sayee R, Priyadharsini M. (2016) Cost-effective feeding of poultry. , International Journal of Science, Environment 5(6), 3997-4005.

- 2.Rudloff B, Mensah K, Wieck C, Kareem O, JML Montesclaros et al. (2024) Geostrategic aspects of policies on food security in the light of recent global tensions–Insights from seven countries.

- 3.Jagtap S, Trollman H, Trollman F, Garcia-Garcia G, Parra-López C et al. (2022) The Russia-Ukraine conflict: Its implications for the global food supply chains. Foods. 11(14).

- 4.Banson K E, Quartey E K, Otoo E A, Baidoo I, Kusi K A et al. (2024) The Economic Value of an Okra Plant. Mod Concepts Dev Agron. 14, 1342-9.

- 5.Banson K E, Muthusamy G, Kondo E. (2015) The import substituted poultry industry; evidence from Ghana. International journal of agriculture and forestry. 5(2), 166-75.

- 6.Andam K S, Johnson M E, Ragasa C, Kufoalor D S, Das Gupta S. (2017) A chicken and maize situation: the poultry feed sector in Ghana: Intl Food Policy Res Inst;.

- 7.Banson K, Muthusamy G, Kondo E. (2015) The import substituted poultry industry; evidence from Ghana.

- 8.Amissah E, Adom D, Adu-Agyem J. (2022) Reducing cost and ensuring environmental sustainability: Palm kernel expeller as an alternative sculpture material for casting in Ghana. , Journal of African History, Culture 2(3), 146-57.

- 9.Faridah H S, Goh Y M, Noordin M M, Liang J B. (2020) Extrusion enhances apparent metabolizable energy, ileal protein and amino acid digestibility of palm kernel cake in broilers. Asian-Australasian journal of animal sciences. 33(12).

- 10.Azizi M N, Loh T C, Foo H L, Teik Chung EL. (2021) Is palm kernel cake a suitable alternative feed ingredient for poultry? Animals. 11-2.

- 11.Kies A, K Van Hemert, Sauer W. (2001) Effect of phytase on protein and amino acid digestibility and energy utilisation. World's Poultry Science Journal. 57(2), 109-26.

- 12.Negm A E, Abo‐Raya M H, Gabr A M, Baloza S H, El‐Nokrashy A et al. (2024) Effects of phytase enzyme supplementation on growth performance, intestinal morphology and metabolism in Nile tilapia (Oreochromis niloticus). , Journal of Animal Physiology and Animal

- 13.Wilkinson J, Young R. (2020) Strategies to reduce reliance on soya bean meal and palm kernel meal in livestock nutrition. , Journal of Applied Animal Nutrition 8(2), 75-85.

- 14.Sharmila A, Alimon A, Azhar K, Noor H, Samsudin A. (2014) Improving nutritional values of Palm Kernel Cake (PKC) as poultry feeds: a review.

- 15.Banson K E. (2024) Beginner's Guide to Pig Production and Management: A Comprehensive Handbook and Training Manual. United kingdom: LAP.

- 16.Banson K E, Asare D K, Dery F D, Boakye K, Boniface A et al. (2020) Impact of fall armyworm on farmer’s maize: systemic approach. Systemic Practice and Action Research. 33, 237-64.

- 17.Anderson R, Bayer P E, Edwards D. (2020) Climate change and the need for agricultural adaptation. Current opinion in plant biology. 56, 197-202.

- 18.Olukomaiya O, Fernando C, Mereddy R, Li X, Sultanbawa Y. (2019) Solid-state fermented plant protein sources in the diets of broiler chickens: A review. Animal Nutrition. 5(4), 319-30.

- 19.Dahiya S. (2016) Role of phytate and phytases in human nutrition. , International Journal of Food Science 1(1), 39-42.

- 20.Alshelmani M I, Bakhashwain A S, Al-Shehri H M. (2016) Effect of dietary supplementation of phytase on the performance, nutrient digestibility and phosphorus excretion in broiler chickens fed diets containing palm kernel cake. , Asian-Australasian Journal of Animal Sciences 29(8), 1090-7.

- 21.Sundu B, Inoue K. (2006) The use of palm kernel cake in broiler diets: An alternative feed ingredient. , Journal of Applied Animal Research 30(2), 85-91.

- 22.Abioja M O, Ayo J O, Adedokun O. (2012) Effect of palm kernel cake and enzyme supplementation on the performance of broiler chickens. , Journal of Animal Science Advances 2(2), 81-8.

- 23.Okeudo N J, Odaibo A B. (2005) Growth performance and carcass characteristics of broilers fed palm kernel cake-based diets. , International Journal of Poultry Science 4(3), 177-81.

- 24.Zhou Y, Jiang Z, Lv D, Wang T. (2009) Improved energy-utilizing efficiency by enzyme preparation supplement in broiler diets with different metabolizable energy levels. Poultry science. 88(2), 316-22.

- 25.Saleh A A, El-Far A H, Abdel-Latif M A, Emam M A, Ghanem R. (2018) Abd El-Hamid HS. Exogenous dietary enzyme formulations improve growth performance of broiler chickens fed a low-energy diet targeting the intestinal nutrient transporter genes. PLoS One. 13-5.

- 28.Sanchez J, Barbut S, Patterson R, Kiarie E. (2021) Impact of fiber on growth, plasma, gastrointestinal and excreta attributes in broiler chickens and turkey poults fed corn-or wheat-based diets with or without multienzyme supplement. Poultry Science. 100(8), 101219.

- 29.Agbede J O, O, A O Ibidapo. (2017) Performance and economic analysis of broiler chickens fed varying levels of palm kernel cake as a replacement for maize. , International Journal of Poultry Science 16(4), 182-9.

- 30.Selle P H, Cowieson A J, Cowieson N P, Ravindran V. (2012) Protein–phytate interactions in pig and poultry nutrition: a reappraisal. Nutrition research reviews. 25(1), 1-17.

- 31.KAH F K. (PKC): University Malaysia Pahang; (2008) . , FORMULATION OF CHICKS FEED BASED ON PALM KERNEL CAKE

- 32.Chong C, Zulkifli I, Blair R. (2008) Effects of dietary inclusion of palm kernel cake and palm oil, and enzyme supplementation on performance of laying hens. , Asian-Australasian Journal of Animal Sciences 21(7), 1053-8.

- 33.Iyayi E A, Davies B I. (2005) Effect of enzyme supplementation of palm kernel meal and brewer’s dried grain on the performance of broilers. , International Journal of Poultry Science 4(2), 76-80.

- 34.Ezieshi E, Olomu J. (2004) Comparative performance of broiler chickens fed varying levels of palm kernel cake and maize offal. Pakistan Journal of Nutrition. 3(4), 254-7.

- 35.Zhai W, E D Peebles, Wang X.Effects of protein and energy levels in diets on the growth performance and profitability of broiler production. , Poultry Science 97(3), 1078-84.

- 36.Tahir M, T N Pasha, F M Khattak.Impact of feed cost optimization on growth performance and economic returns in poultry. , Journal of Applied Poultry Research 30(2), 249-58.

- 37.Roura E, Koopmans S-J, Lallès J-P, I Le Huerou-Luron, N de Jager et al. (2016) Critical review evaluating the pig as a model for human nutritional physiology. Nutrition research reviews. 29(1), 60-90.

- 39.Ravindran V, Cabahug S, Ravindran G, Bryden W. (1999) Influence of microbial phytase on apparent ileal amino acid digestibility of feedstuffs for broilers. Poultry Science. 78(5), 699-706.

- 40.Sundu B, Kumar A, Dingle J. (2006) Palm kernel meal in broiler diets: effect on chicken performance and health. World's Poultry Science Journal. 62(2), 316-25.

- 41.Cowieson A, Bedford M, Selle P, Ravindran V. (2009) Phytate and microbial phytase: implications for endogenous nitrogen losses and nutrient availability. World's poultry science journal. 65(3), 401-18.

- 42.Liu N, Ru Y, Li F, Cowieson A. (2008) Effect of diet containing phytate and phytase on the activity and messenger ribonucleic acid expression of carbohydrase and transporter in chickens. Journal of animal science. 86(12), 3432-9.

- 43.Mottet A, Tempio G. (2017) Global poultry production: current state and future outlook and challenges. World's poultry science journal. 73(2), 245-56.

- 44.Heckert R, Estevez I, Russek-Cohen E, Pettit-Riley R. (2002) Effects of density and perch availability on the immune status of broilers. Poultry Science. 81(4), 451-7.

- 45.Keshavarz K, Nakajima S. (2016) Phytase supplementation in diets and its effects on laying hens’ performance and nutrient retention. Poultry Science. 95(9), 2243-50.

- 46.Singh A K, Kim W K. (2021) Effects of dietary fiber on nutrients utilization and gut health of poultry: a review of challenges and opportunities. Animals. 11-1.

- 47.Woyengo T, Nyachoti C. (2011) Supplementation of phytase and carbohydrases to diets for poultry. , Canadian Journal of Animal Science 91(2), 177-92.

- 48.Omeje S I, A O. (2009) Effects of varying levels of palm kernel cake on performance and egg quality of laying hens. , International Journal of Poultry Science 8(5), 484-8.

- 49.Aro S O, Kehinde-Olayanju O A, Aletor V A, Adegbeye M J, Elghandour M M et al. (2022) Effect of microbial-fermented cassava wastes as dietary replacement for ground maize on cockerel production. Waste and Biomass Valorization. 1-7.

- 50.Sarkar P, Chowdhury S, Kabir M, Sarker P. (2008) Comparative study on the productivity and profitability of commercial broiler, cockerel of a layer strain and cross-bred (Rir× Fayoumi) Chicks. , Bangladesh Journal of Animal Science 37(2), 89-98.

- 51.Swennen Q, Verhulst P-J, Collin A, Bordas A, Verbeke K et al. (2007) Further investigations on the role of diet-induced thermogenesis in the regulation of feed intake in chickens: Comparison of adult cockerels of lines selected for high or low residual feed intake. Poultry science. 86(9), 1960-71.

- 52.Singh P. (2008) Significance of phytic acid and supplemental phytase in chicken nutrition: a review. World's Poultry Science Journal. 64(4), 553-80.